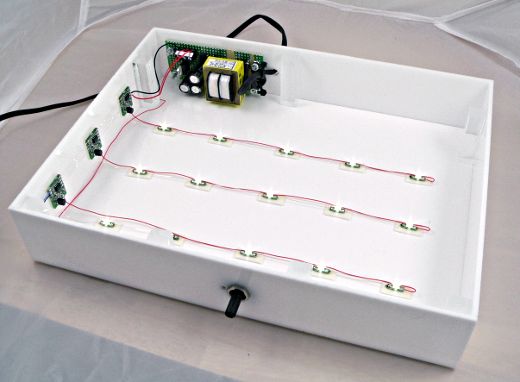

In my slow but steady quest for better macro photography of electronic projects, I decided to build a light table to (hopefully) eliminate shadows.

With boards from

Laen's PCB group order, materials from

TAP Plastics, 15 white LEDs and misc parts I mostly had laying around, this is how it turned out:

Read on for electronic details....

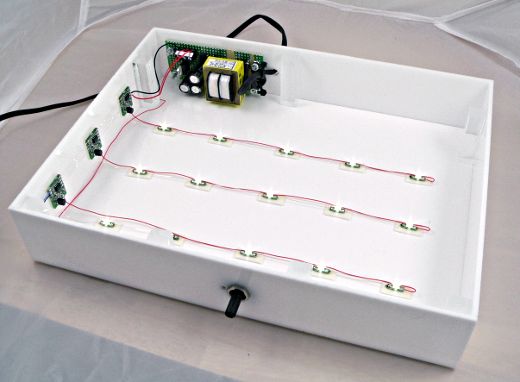

This view is inside a cheap 2 foot sized light tent I purchased from some ebay vendor, and a couple bright lights outside the tent on both side.

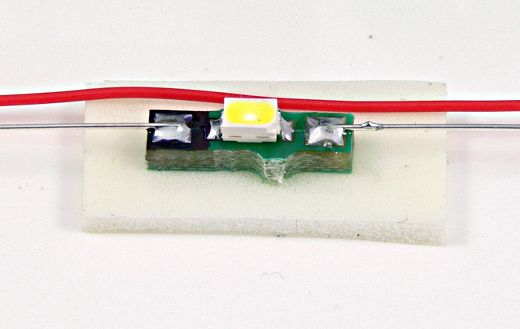

The LEDs are

Cree CLM3C-WKW-CWBYA453, which are supposedly the same 5500K color temperature as the CFL lights outside the tent. Maybe that matters, maybe not, but it seemed like a good idea.

The Cree LED is a surface mount part, but fortunately Lean's PCB group order made it

very easy to convert to something I can solder wires onto. All the PCBs mount with

double sticky mounting tape.

As you can see in this LED photo, there's a bit of shadow. It's a soft

shadow due to the light tent casting light from many directions, but it's

still very present. This is the type of shadow I'm hoping just a little bit

of under side lighting will eliminate.

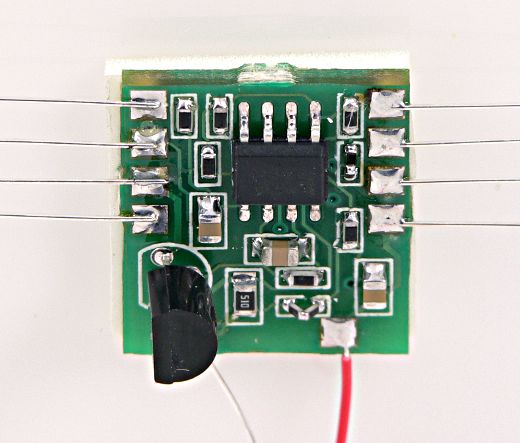

This little board is a contant current regulator. It takes a 0 to 5 volt input

and regulates a 0 to 20 mA output current to a string of 5 LEDs. I wanted to make

sure the current was perfectly contant since the camera might choose a quick

shutter time.

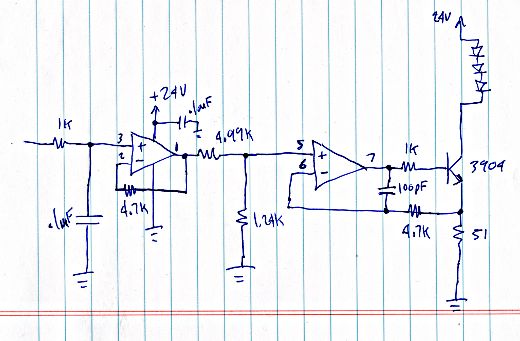

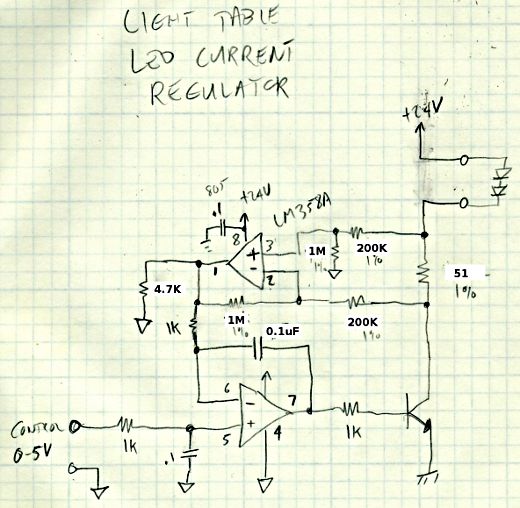

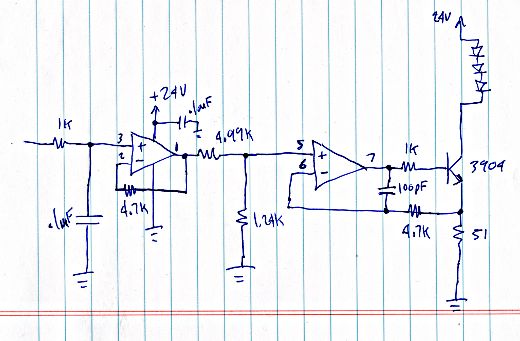

Here's the schematic for that circuit. At the time, it seemed like a good

idea to sense the current using a resistor between the NPN transistor's

collector and the LEDs. The idea was any small change in ground potential

between the board 0-5V control signal wouldn't matter, if I ran separate

signal and power ground lines.

But I didn't consider the current draw though those resistors around the

upper opamp. As you can see in the schematic, I change the values to

about as high as I reasonably could. It still have a tiny bit of the

lowest part of the range where the LEDs won't completely turn off.

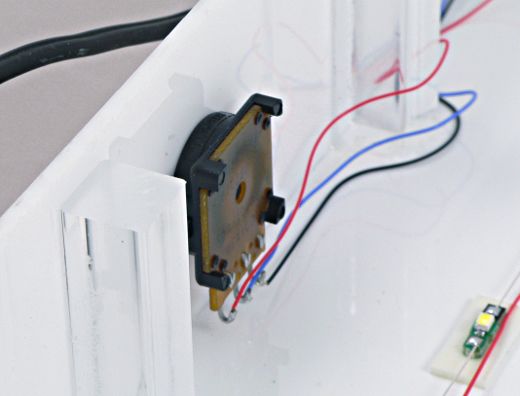

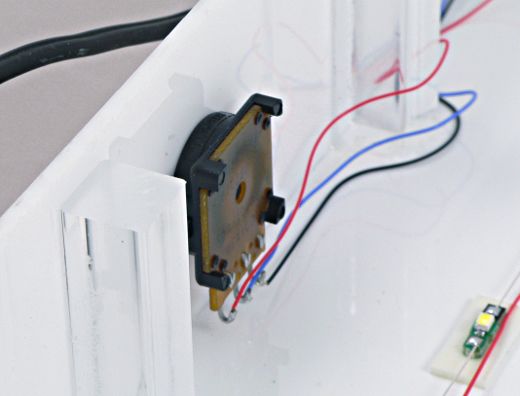

The 0 to 5 volt signal just comes from this potentiometer on the front

panel. Because it's driving only the inputs to opamps, it doesn't have

any substantial load. I still used a 1K pot anyways, though a higher

value would have consumed a little less current. I guess I didn't care

about an extra 5 mA.

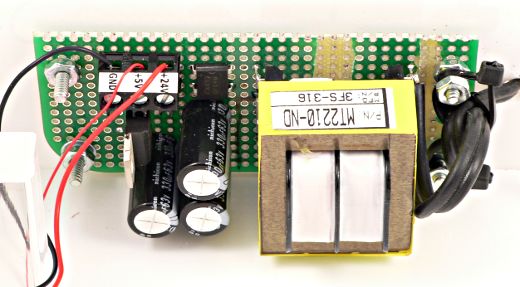

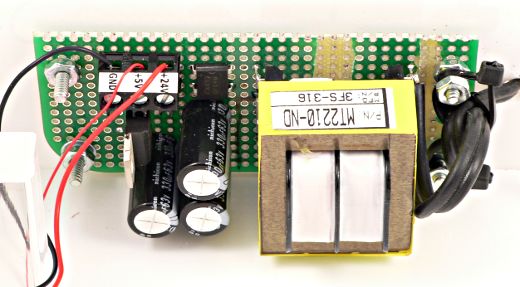

The power for everything comes from this simple little power supply,

which is just (approx) 24 volts unregulated, and a 5 volt regulated

output from the pot, which is from a 7805 regulator. Simple.

Of course, the opamp circuit isn't perfect. After putting this together,

I decided to try a different approach, sensing on the emitter side, and

no current sensing path to add to the LED current! I

also included 4.7K resistors on the feedback looks, and the positive

inputs see about a 1K impedance. Any errors from the opamp's input

(PNP) bias currents should be small, and shoud be more on the negative

than positive, so hopefully any tiny error will tend to redude the LED

current, not increase.

Then again, the original boards might work out ok, but Laen's PCB

group order makes it so very easy to just quickly draw up a (small)

board. Because the cost is so low, it's easy to just send it off

without all the worry the goes into a normal board order.

I still haven't actually put this thing to use... the top plastic cover

turned out to be just a bit too small, so I need to go shave it down

to size on my table saw (which currently has a bunch of other project

stuff piled on top of it). But soon, with a little luck, I'll be able

to take pictures of electronic stuff and adjust the light table to

null out or at least soften away most of the little shadows that I still

get, even with the light tent.

Read on for electronic details....

This view is inside a cheap 2 foot sized light tent I purchased from some ebay vendor, and a couple bright lights outside the tent on both side.

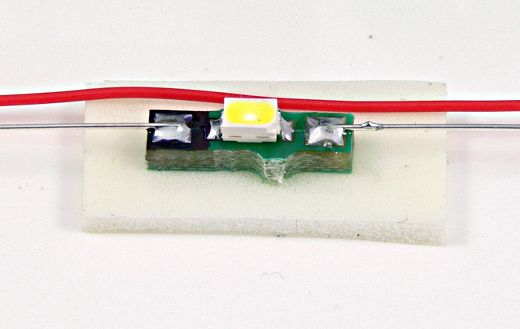

The LEDs are Cree CLM3C-WKW-CWBYA453, which are supposedly the same 5500K color temperature as the CFL lights outside the tent. Maybe that matters, maybe not, but it seemed like a good idea.

The Cree LED is a surface mount part, but fortunately Lean's PCB group order made it

very easy to convert to something I can solder wires onto. All the PCBs mount with

double sticky mounting tape.

Read on for electronic details....

This view is inside a cheap 2 foot sized light tent I purchased from some ebay vendor, and a couple bright lights outside the tent on both side.

The LEDs are Cree CLM3C-WKW-CWBYA453, which are supposedly the same 5500K color temperature as the CFL lights outside the tent. Maybe that matters, maybe not, but it seemed like a good idea.

The Cree LED is a surface mount part, but fortunately Lean's PCB group order made it

very easy to convert to something I can solder wires onto. All the PCBs mount with

double sticky mounting tape.

As you can see in this LED photo, there's a bit of shadow. It's a soft

shadow due to the light tent casting light from many directions, but it's

still very present. This is the type of shadow I'm hoping just a little bit

of under side lighting will eliminate.

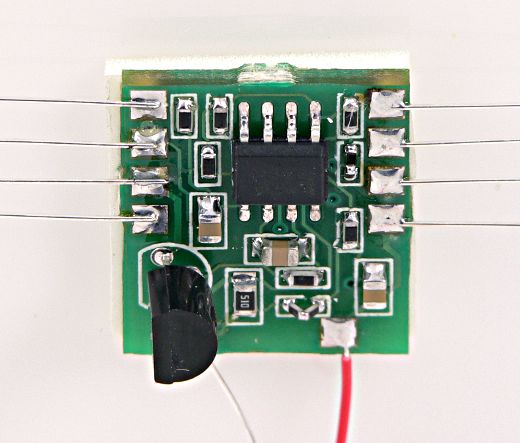

This little board is a contant current regulator. It takes a 0 to 5 volt input

and regulates a 0 to 20 mA output current to a string of 5 LEDs. I wanted to make

sure the current was perfectly contant since the camera might choose a quick

shutter time.

As you can see in this LED photo, there's a bit of shadow. It's a soft

shadow due to the light tent casting light from many directions, but it's

still very present. This is the type of shadow I'm hoping just a little bit

of under side lighting will eliminate.

This little board is a contant current regulator. It takes a 0 to 5 volt input

and regulates a 0 to 20 mA output current to a string of 5 LEDs. I wanted to make

sure the current was perfectly contant since the camera might choose a quick

shutter time.

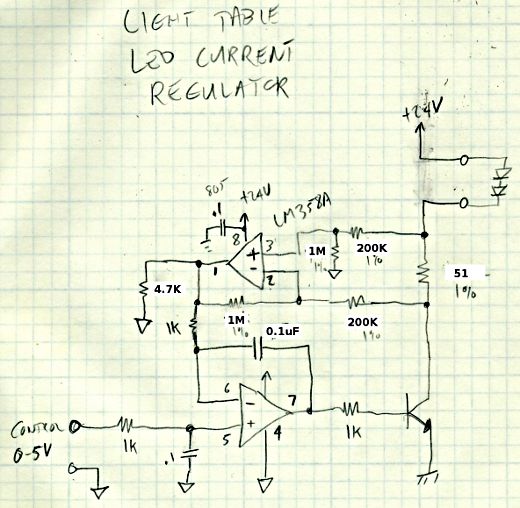

Here's the schematic for that circuit. At the time, it seemed like a good

idea to sense the current using a resistor between the NPN transistor's

collector and the LEDs. The idea was any small change in ground potential

between the board 0-5V control signal wouldn't matter, if I ran separate

signal and power ground lines.

But I didn't consider the current draw though those resistors around the

upper opamp. As you can see in the schematic, I change the values to

about as high as I reasonably could. It still have a tiny bit of the

lowest part of the range where the LEDs won't completely turn off.

Here's the schematic for that circuit. At the time, it seemed like a good

idea to sense the current using a resistor between the NPN transistor's

collector and the LEDs. The idea was any small change in ground potential

between the board 0-5V control signal wouldn't matter, if I ran separate

signal and power ground lines.

But I didn't consider the current draw though those resistors around the

upper opamp. As you can see in the schematic, I change the values to

about as high as I reasonably could. It still have a tiny bit of the

lowest part of the range where the LEDs won't completely turn off.

The 0 to 5 volt signal just comes from this potentiometer on the front

panel. Because it's driving only the inputs to opamps, it doesn't have

any substantial load. I still used a 1K pot anyways, though a higher

value would have consumed a little less current. I guess I didn't care

about an extra 5 mA.

The 0 to 5 volt signal just comes from this potentiometer on the front

panel. Because it's driving only the inputs to opamps, it doesn't have

any substantial load. I still used a 1K pot anyways, though a higher

value would have consumed a little less current. I guess I didn't care

about an extra 5 mA.

The power for everything comes from this simple little power supply,

which is just (approx) 24 volts unregulated, and a 5 volt regulated

output from the pot, which is from a 7805 regulator. Simple.

The power for everything comes from this simple little power supply,

which is just (approx) 24 volts unregulated, and a 5 volt regulated

output from the pot, which is from a 7805 regulator. Simple.

Of course, the opamp circuit isn't perfect. After putting this together,

I decided to try a different approach, sensing on the emitter side, and

no current sensing path to add to the LED current! I

also included 4.7K resistors on the feedback looks, and the positive

inputs see about a 1K impedance. Any errors from the opamp's input

(PNP) bias currents should be small, and shoud be more on the negative

than positive, so hopefully any tiny error will tend to redude the LED

current, not increase.

Of course, the opamp circuit isn't perfect. After putting this together,

I decided to try a different approach, sensing on the emitter side, and

no current sensing path to add to the LED current! I

also included 4.7K resistors on the feedback looks, and the positive

inputs see about a 1K impedance. Any errors from the opamp's input

(PNP) bias currents should be small, and shoud be more on the negative

than positive, so hopefully any tiny error will tend to redude the LED

current, not increase.

Then again, the original boards might work out ok, but Laen's PCB

group order makes it so very easy to just quickly draw up a (small)

board. Because the cost is so low, it's easy to just send it off

without all the worry the goes into a normal board order.

I still haven't actually put this thing to use... the top plastic cover

turned out to be just a bit too small, so I need to go shave it down

to size on my table saw (which currently has a bunch of other project

stuff piled on top of it). But soon, with a little luck, I'll be able

to take pictures of electronic stuff and adjust the light table to

null out or at least soften away most of the little shadows that I still

get, even with the light tent.

Then again, the original boards might work out ok, but Laen's PCB

group order makes it so very easy to just quickly draw up a (small)

board. Because the cost is so low, it's easy to just send it off

without all the worry the goes into a normal board order.

I still haven't actually put this thing to use... the top plastic cover

turned out to be just a bit too small, so I need to go shave it down

to size on my table saw (which currently has a bunch of other project

stuff piled on top of it). But soon, with a little luck, I'll be able

to take pictures of electronic stuff and adjust the light table to

null out or at least soften away most of the little shadows that I still

get, even with the light tent.