I've always made PCB's by the Photo fab method, with varying but never entirely satisfactory results. I was also somewhat put off by the need to buy pre-sensitized boards, at ridiculous prices. at a meeting earlier this year I was talking to Don ( feurig ) about it and he suggested I try the Toner Transfer Method (note reverent capitals).

I'm completely hooked on the toner method. There are a ton of tutorials on using glossy ink-jet photo paper to do it, but don't bother get the good stuff from pulsar (digikey part number 182-1021-ND0 ). using the photo paper is a pain. you have to soak and scrub and mess around instead of just getting the paper wet and pulling it off.

But the Secret Sauce is Digikey part number 182-1021-ND also known as Green TRF.

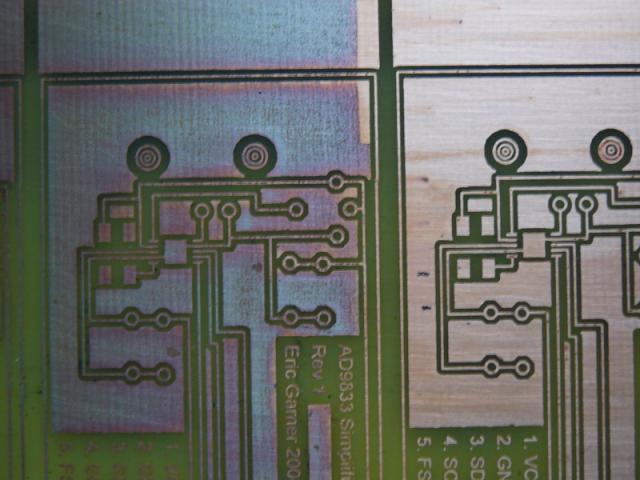

The difference between Green TRF and no TRF is pretty obvious:

On the board on the left is the Toner Transfer Paper alone, and on the right I also used the Green TRF.

The other thing than makes toner transfer a treat is using a laminator. I use a GBC HeatSeal H110 (for no particular reason other than it was on sale at Office Depot that day.)

The big trick to using the laminator with TRF is to put he laminator on the "cool" setting,after warming it up a bit, not all the way on the "hot" setting, to get the wrinkles out of it before you do it with the laminator fully heated. if you don't do this the TRF smudges a bit.

Using the laminator with the Toner Transfer Paper is cake, just heat the laminator up and pass the board through a few times