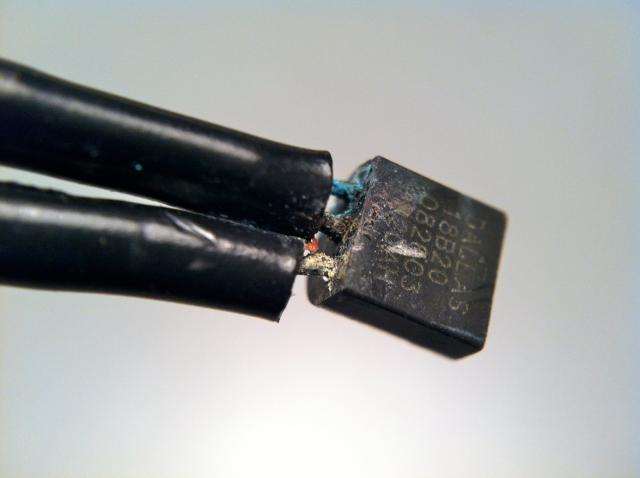

After two years of service my outdoor air temperature sensor blinked out last week. Moisture was the culprit as shown here:

Various readouts in my SensorServer system lead me straight to the problem through a half-dozen layers of software. How cool is that?

Honestly, I'm more interested in how we know and trust complex measurements than knowing the temperature outside.

My SensorServer software worked so well that I prepared a Keynote presentation explaining each diagnostic step along the way. I meant to post it here, but damn, low battery led Keynote to throw away my presentation. That makes Apple the weak link, no?

I see a lot of broken systems in our future. A robust world will depend more on diagnosis and recovery than on the out-of-the-box usability that has made Apple famous.