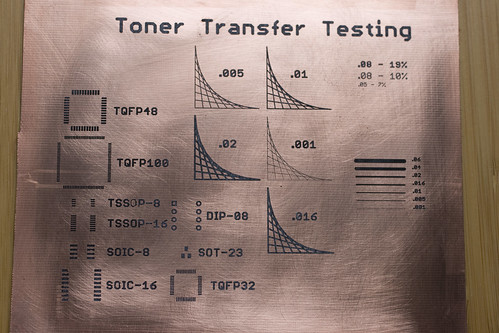

I spent some time over the weekend trying to see what my board etching capabilities actually are. I use toner transfer, and I thought that kind of limited my options, as far as how fine of detail I could get. I made

this test pattern with a variety of surface mount components and line sizes, then tried to transfer them to copper with a couple of different methods.

First, I used a clothes iron, several different temperature settings and applying differing amounts of pressure. This is the one that turned out the best:

(

Full resolution)

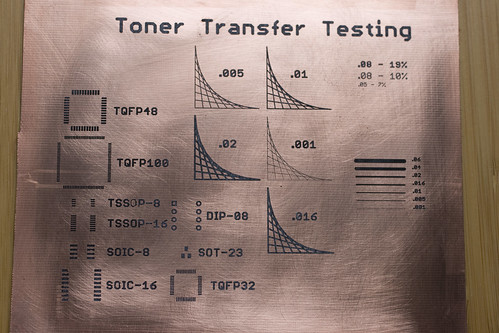

Then, I switched to a laminator. After sending it through a dozen times (top and bottom), I got this:

(

Full Resolution)

MUCH better. I can do .001" lines sometimes, and .005" lines consistently. I can _almost_ do TFQP-100, and I can certainly do any of the other TQFPs.

(Full resolution)

Then, I switched to a laminator. After sending it through a dozen times (top and bottom), I got this:

(Full resolution)

Then, I switched to a laminator. After sending it through a dozen times (top and bottom), I got this:

(Full Resolution)

MUCH better. I can do .001" lines sometimes, and .005" lines consistently. I can _almost_ do TFQP-100, and I can certainly do any of the other TQFPs.

(Full Resolution)

MUCH better. I can do .001" lines sometimes, and .005" lines consistently. I can _almost_ do TFQP-100, and I can certainly do any of the other TQFPs.